Printer 900 depth x 1150 width x 1705 height

Paper processor 100 m/h and 150 m/h see below:

LASERLAB Internal View

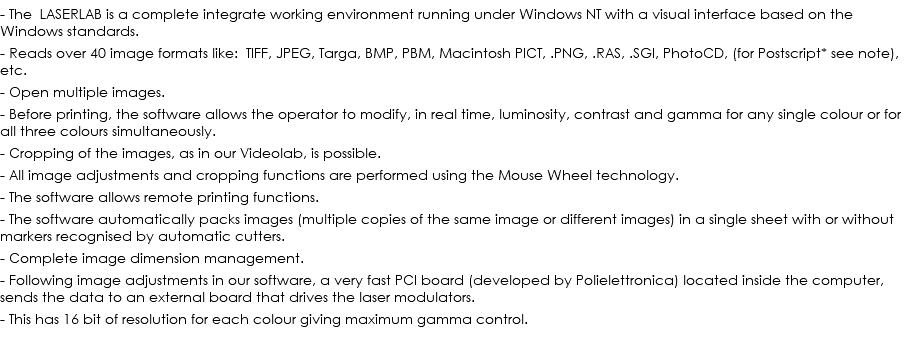

Laserlab Production Rates Per Hour

Paper Processor

8"x 6"

10"x 8"

20"x 24"

20"x 32"

30"x49"

Based on 12 prints on a 20"x32"

Based on 8 prints on a 20"x32"

100 m/h

1872

1248

156

120

70

150 m/h

2495

1664

190

160

-

Paper Processor Tanks Volume (litres)

Paper Processor

Developer

Bleach

Stabiliser

Replenishment tanks

Overflow tanks

100 m/h

1 x 28

1 x 28

3 x 21

3 x 30

3 x 20

150 m/h

2 x 19

2 x 19

3 x 25

3 x 30

3 x 20

Tel: +44 20 8441 4310

FAX: +44 20 8449 0317

Leopold Professional Imaging, Colex House, 57 Lancaster Road, New Barnet, Herts,EN4 8AS, England